Customizable HPGR Carbide Edge Block with TRS > 3000 N/mm3 and Hardness 85-92 HRA for High-Pressure Grinding Roller

Szczegóły Produktu:

| Miejsce pochodzenia: | Hunan, Chiny |

| Nazwa handlowa: | Rixin |

| Numer modelu: | Kołek z węglika wolframu-3 |

Zapłata:

| Minimalne zamówienie: | 10 |

|---|---|

| Cena: | $59 |

|

Szczegóły informacji |

|||

| Tworzywo: | Węglenie wolframowe | Obróbka powierzchni: | Zakończ uziemiony |

|---|---|---|---|

| Stopień: | YG11C, YG15, YG15C, YG18, YG20 | Rozmiar: | Dostosowane |

| TRS: | > 3000 N/mm3 | Twardość: | 85-92 HRA |

| Life Service: | 10000 - 30000 godzin | Źródło zasilania: | Elektryczny |

| Typ silnika: | Elektryczny | Powierzchnia: | Pokryty |

| Stosowanie: | Wałek szlifierski pod wysokim ciśnieniem, ruda żelaza, kruszenie cementu | Wydajność: | Wysoka twardość, wytrzymałość, odporność na uderzenia |

| Indywidualne wsparcie: | OEM | Gęstość: | Wysoki |

| Odporność na uderzenia: | Wysoki | ||

| Podkreślić: | TRS > 3000 N/mm3 HPGR Carbide Edge Block,Hardness 85-92 HRA Tungsten Carbide Edge Block,Service Life 10000-30000hrs HPGR Edge Block |

||

opis produktu

OEM Customizable HPGR Tungsten Carbide Edge Block for High-Pressure Grinding Roller Iron Tool Parts with Finishing Surface

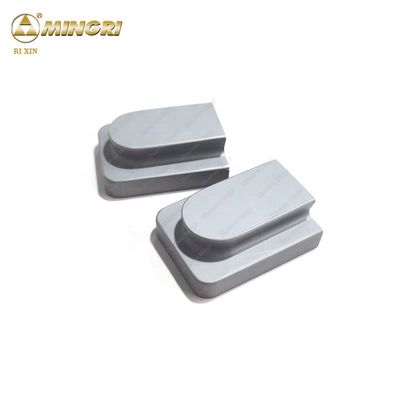

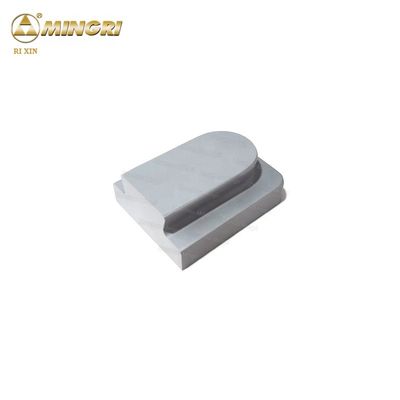

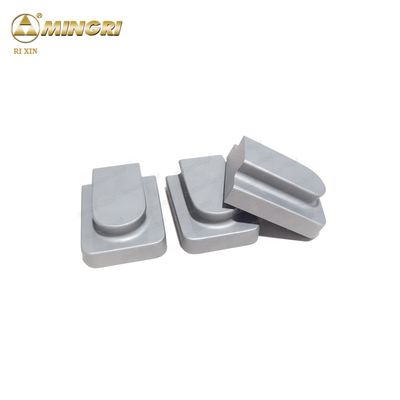

HPGR Carbide Edge Block for high pressure grinding roller

| Item | Tungsten carbide edge block |

|---|---|

| Grade | YG11C, YG15, YG15C, YG18, YG20 |

| Sizes | Standard or customized |

| Brand | Rixin |

| Country of Origin | Zhuzhou, China |

| Usage | High pressure grinding roller, iron ore, cement crushing |

Tungsten carbide edge blocks are widely used on the rollers of High Pressure Grinding Roll. With good properties of high hardness, strength and impact resistance, the service life and work efficiency of HPGR machines can be greatly improved. Comparing to the traditional hardfacing rollers, service life of tungsten carbide edge block will be 10 times longer.

Grade and Usage

Size and Types

Package and Delivery

Main Products

We are specialized in all kinds of tungsten carbide profiles and dies, cutting tools, mining tools, wear parts and all kinds of non-standard customized tool parts with high performance in the industry.

Company Info

Workshop

We have powder mixing, pressing, sintering, finishing, surface treatment, mould design workshops and physical and chemical labs for inspection. We have hundreds of updated equipments to make sure month capacity 50 tons and excellent quality.

Production & Testing

All the products must be inspected strictly with the ultrasonic and only those haven't any harm such as pore can be shipped out. High density, high wear & impact resistance, which lead them a long lifetime.

Team and Exhibitions

Contact

Chcesz dowiedzieć się więcej o tym produkcie