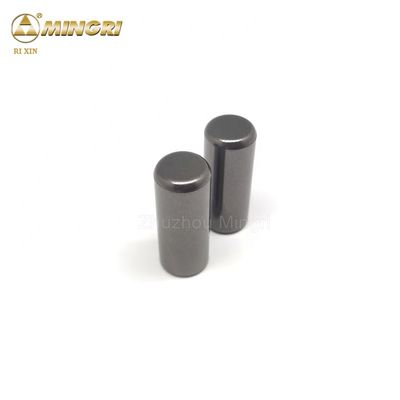

Durable Anti-Wear Customized Tungsten Carbide Studs for HPGR Rollers and Cement Grinding

Szczegóły Produktu:

| Miejsce pochodzenia: | Chiny |

| Nazwa handlowa: | Rixin |

| Numer modelu: | 16x40 |

Zapłata:

| Minimalne zamówienie: | 1 |

|---|

|

Szczegóły informacji |

|||

| Specyfikacja stopu: | MR151 | Cząstka: | 2 |

|---|---|---|---|

| Tworzywo: | Węglenie wolframowe | Obróbka powierzchni: | Zakończ uziemiony |

| TRS: | > 3000 N/mm3 | Twardość: | 85-92 HRA |

| Life Service: | 10000-30000 godzin | Gęstość: | 14,4-13,5 g/cm3 |

| Średnica: | 10-20 mm | Wysokość: | 20-70 mm |

| kopuła: | SR5-SR10 | ścięcie: | R1.0-R5.0 |

| Przybliżona waga: | 108-172 g | Klas: | YG11C, YG15, YG15C, YG18, YG20 |

| Pojemność miesięczna: | 50 ton | ||

| Podkreślić: | Durable Tungsten Carbide Studs,Anti-Wear HPGR Studs,Customized Cemented Carbide Studs |

||

opis produktu

Durable & Anti-Wear Tungsten Carbide Studs for HPGR Rollers Cement Grinding

High performance cemented carbide studs designed for High Pressure Grinding Rollers (HPGR), offering exceptional wear resistance and extended service life in cement clinker, limestone, bauxite, and iron ore applications.

Product Specifications

| Item | Details |

|---|---|

| Type | Cemented Carbide |

| Grade | YG11C, YG15, YG15C, YG18, YG20 |

| Sizes | Standard or customized |

| Brand | Rixin |

| Origin | Zhuzhou, China |

| Usage | High pressure grinding roller, iron ore, cement crushing |

Grade Specifications

| Grades | Density (g/cm³) | Hardness (HRA) | T.R.S ≥N/mm² |

|---|---|---|---|

| RX-11 | 14.4 | 87 | 2700 |

| RX-15 | 14 | 87 | 3000 |

| RX650 | 13.8 | 88.2 | 3100 |

| RX20 | 13.5 | 85.5 | 3200 |

* Other grades available upon customer request.

Key Advantages

- Service life: 8000-10000 hours for iron ore crushing and over 25000 hours for cement crushing

- Total production capacity: over 800 tons of HPGR studs

- Excellent wear resistance and high compressive strength

- Custom sizes and grades available

Standard Sizes

Reference dimensions for High Pressure Grinding Roll Carbide Studs (mm):

| Diameter | Height | Dome | Chamfer |

|---|---|---|---|

| 20 | 40 | SR10 | 2xR5.0 |

| 20 | 35 | SR10 | 2xR5.0 |

| 20 | 30 | SR10 | 2xR5.0 |

| 16 | 55 | SR8 | R2.0 |

| 16 | 45 | SR8 | 2xR5.0 |

Quality Assurance

All products undergo strict ultrasonic inspection to ensure no internal defects. Our carbide studs feature high density, superior wear resistance, and impact resistance for maximum service life.

Manufacturing Capabilities

Our facility includes powder mixing, pressing, sintering, finishing, and surface treatment workshops with complete physical and chemical labs for quality control. Monthly production capacity exceeds 50 tons.

Contact Information

Phone: 0086-15886314519

Chcesz dowiedzieć się więcej o tym produkcie